Have you ever wondered how long it takes for tap water to distill? Understanding the distillation process and its time frame can be quite useful, especially if you’re considering purifying water for your home or even for a specific project. Distilling your own water is an old and reliable method to remove impurities and ensure that your water is as clean and pure as possible. This guide will walk you through everything you need to know about the process and how much time you should allot for it.

What Is Distillation?

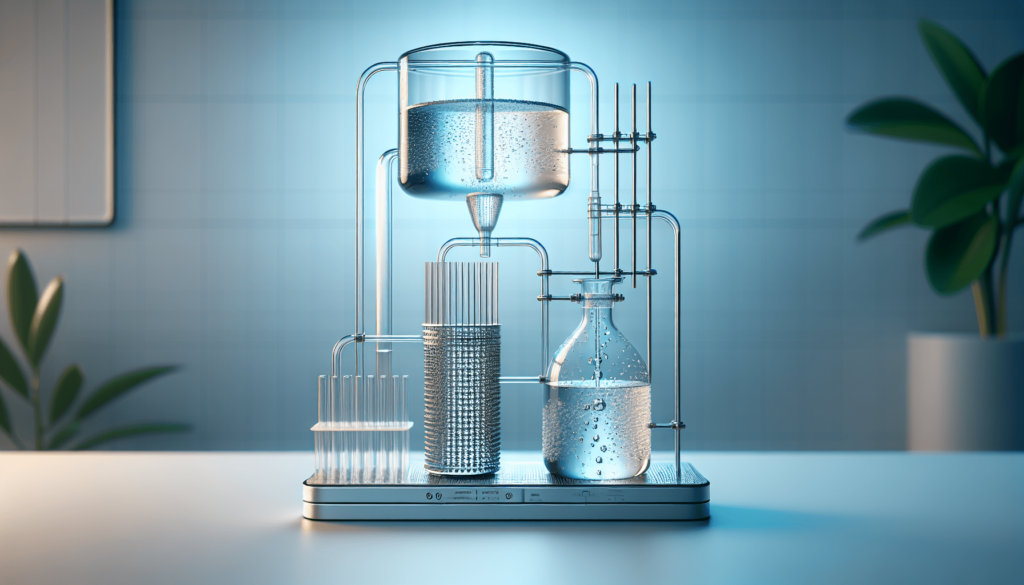

Distillation is a purification process that involves heating water to create steam, then cooling that steam back into liquid water. The impurities do not vaporize and remain in the original container. It’s a method used to ensure that water is free from contaminants like bacteria, minerals, and other impurities.

Why Distill Water?

Water distillation is more than just an old-fashioned method; it’s a time-tested way to ensure purity. While filters are effective in their ways, distillation provides one of the most thorough forms of purification. By vaporizing and then condensing the water, you strip out contaminants and end up with pure H₂O.

Some reasons you might opt to distill water include:

- Enhancing the taste and quality of drinking water

- Laboratory use where pure water is essential

- Distilling water for humidifiers to prevent mineral buildup

- Removing specific contaminants that regular filters may miss

Factors Influencing Distillation Time

You might be curious about the time frame for distilling tap water. Several factors can affect how long the process takes:

Quality of Source Water

The initial quality of your tap water can influence the distillation time. Water that is heavily loaded with minerals, sediments, or other contaminants may take longer to distill. The process will work, but you might notice that the equipment requires more maintenance and attention.

Volume of Water

The amount of water you plan to distill plays a significant role in how long it will take. Distilling just a liter or two will understandably be faster than distilling gallons of water.

Distillation Equipment

The type of distillation equipment you use also affects the time. Home distillation units may take longer than industrial ones due to their size and power. Additionally, the efficiency of these units can vary, with some featuring faster heating elements and more effective cooling systems.

Heat Source

The intensity and stability of your heat source will also affect the distillation time. A steady, high heat source will expedite the process, whereas inconsistent or lower heat will naturally prolong it.

Step-by-Step Guide to Distilling Tap Water

If you’re set on distilling your tap water, here’s a step-by-step guide on how to do it.

Equipment You’ll Need

- Distillation Unit: This could be a countertop distiller designed for home use or a more elaborate setup if you’re up for some DIY.

- Heat Source: Usually integrated for home distillers, but if you’re doing this manually, a stove or portable burner works.

- Collecting Container: Where the distilled water will be stored.

- Cooling System: Some mechanism to cool the vapor back into the water; many home distillers have this built-in.

The Distillation Process

- Fill the Boiler: Start by filling the distiller’s boiler with tap water. Avoid overfilling as this might cause spills and uneven distillation.

- Heat the Water: Turn on the heat source and begin heating the water. For many home distillers, this is as simple as pressing an ‘on’ button.

- Vaporization: As the water heats up, it will convert into steam, leaving most contaminants behind in the boiler.

- Cooling: The steam then travels through a cooling system where it condenses back into liquid water. This is often an integrated coil mechanism that cools the vapor.

- Collection: The distilled water drips into a clean collecting container. Ensure the container is sterile to avoid introducing new impurities.

Average Time for Distillation

Given the variables, it’s challenging to pin down an exact time frame, but here’s a general idea:

| Quantity of Water | Estimated Time Needed |

|---|---|

| 1 liter | 1-2 hours |

| 4 liters | 4-6 hours |

| 10 liters | 8-10 hours |

Home Distillers vs. Industrial Distillers

Home distillation units are smaller and designed for personal use, typically handling 3-6 liters at a time. These units often take several hours to complete a single batch. For instance, a home unit holding 4 liters might need around 4-6 hours.

Industrial distillers, however, are more powerful and can process a larger volume of water in a shorter time. These units are used for commercial purposes and are designed to handle anywhere from 10 to hundreds of liters, sometimes concluding a cycle within a few hours.

Maintenance and Cleaning

Maintaining your distillation equipment is vital to ensure longevity and effective operation. Over time, residues from contaminants can build up in the boiler and cooling systems. Regular cleaning is necessary, typically after each use or at least weekly, depending on frequency.

Cleaning Steps

- Unplug and Disassemble: Always ensure the unit is unplugged and completely cool before taking it apart.

- Cleaning the Boiler: Use a mixture of vinegar and water to scrub out any mineral buildup or use specialized descaling solutions.

- Cleaning the Condenser: This might be a bit trickier but equally essential. Follow manufacturer guidelines for the best method.

- Drying and Reassembly: Always let each part dry fully before putting it back together to avoid mold or residual moisture.

Is Distilled Water the Best Option?

Distilled water is pure but lacks minerals, which are often beneficial for health. For most people, drinking mineralized water is perfectly fine and sometimes even preferred for its taste and health benefits.

Comparing Distilled and Filtered Water

| Aspect | Distilled Water | Filtered Water |

|---|---|---|

| Purity Level | High, nearly 100% pure | Varies by filter type |

| Mineral Content | None | Usually retains some minerals |

| Taste | Neutral | Can vary, often tastes better |

| Equipment Needed | Distillation Unit | Water filter |

| Time to Process | Several hours | Almost immediate |

| Cost | Higher initial investment | Lower, depending on filter type |

Applications Beyond Drinking

Distilled water has various uses beyond just drinking. It’s often used in laboratory settings, for car maintenance (like batteries and coolant systems), and in household appliances like irons and humidifiers to prevent mineral buildup.

Common Uses

- Medical and Laboratory: Essential for ensuring no contaminants interfere with tests or procedures.

- Automotive: Helps in car batteries and coolant systems, preventing corrosion and mineral deposits.

- Household Appliances: Keeps irons, humidifiers, and CPAP machines from developing scale and deposits.

Expense and Considerations

While distilling your tap water sounds appealing, be aware of the associated costs and time investment. Home distillers can range from $100 to $300, while industrial models are significantly more expensive. The ongoing cost includes electricity and periodic maintenance supplies like descalers or cleaning agents.

Initial vs. Ongoing Costs

| Expense Type | Estimated Cost |

|---|---|

| Home Distiller Unit | $100 – $300 |

| Industrial Distiller | $1,000 – $5,000+ |

| Monthly Electricity | $10 – $20 (Home Use) |

| Cleaning Supplies | $5 – $15 per month |

Summary and Final Thoughts

Distilling tap water is a thorough purification method removing nearly all contaminants, making it a preferred choice for specific applications where purity is paramount. However, the time and costs associated with the distillation process can be significant, which isn’t always ideal for everyday use.

Considering the initial investment, maintenance, and electricity, it’s crucial to weigh the benefits against your needs. Distilled water is exceptionally pure and beneficial for specialized uses, but for most regular applications, good quality filtered water may suffice.

Remember, whether you’re looking to improve your drinking water or need pure water for particular tasks, understanding how long it takes and the factors involved in the distillation process can help you make informed decisions. Investing in the right equipment and maintaining it well ensures you get the best results, making the process worthwhile.