Are you aware of the differences between on-demand and continuous methods for purifying drinking water? As concerns about water quality rise, understanding these methods is crucial.

Water distillation is a vital process for removing impurities, and both on-demand and continuous distillation have their unique applications and benefits. While on-demand distillation provides a fresh supply as needed, continuous distillation offers a consistent output, catering to different needs and preferences.

Key Takeaways

- Understanding the differences between on-demand and continuous distillation is essential for choosing the right method.

- On-demand distillation provides a fresh supply of distilled water as needed.

- Continuous distillation offers a consistent output, suitable for larger or more consistent demands.

- Both methods have unique applications and benefits.

- The choice between on-demand and continuous distillation depends on specific needs and preferences.

Understanding Water Distillation Basics

Understanding the basics of water distillation is crucial for appreciating its role in water purification. Water distillation is a process that separates components based on differences in boiling points, effectively removing contaminants from water.

The Science Behind Water Distillation

Water distillation works on the principle that water and its contaminants have different boiling points. When water is heated to its boiling point, it turns into steam, leaving behind impurities such as salts, heavy metals, and other contaminants. This steam is then cooled and condensed back into liquid form, resulting in purified water. The science behind distillation is rooted in the physical properties of water and its contaminants, making it a reliable water purification method.

Why Distillation Matters for Water Purification

Distillation matters significantly for water purification because it can remove a wide range of contaminants, including dissolved solids, bacteria, viruses, and other pathogens. Unlike some other water purification methods, distillation can produce water that is very close to being completely pure. This makes it an essential distillation technique in various applications, from drinking water production to industrial processes.

By understanding the basics of water distillation, individuals can make informed decisions about their water purification needs, whether for personal use or industrial applications.

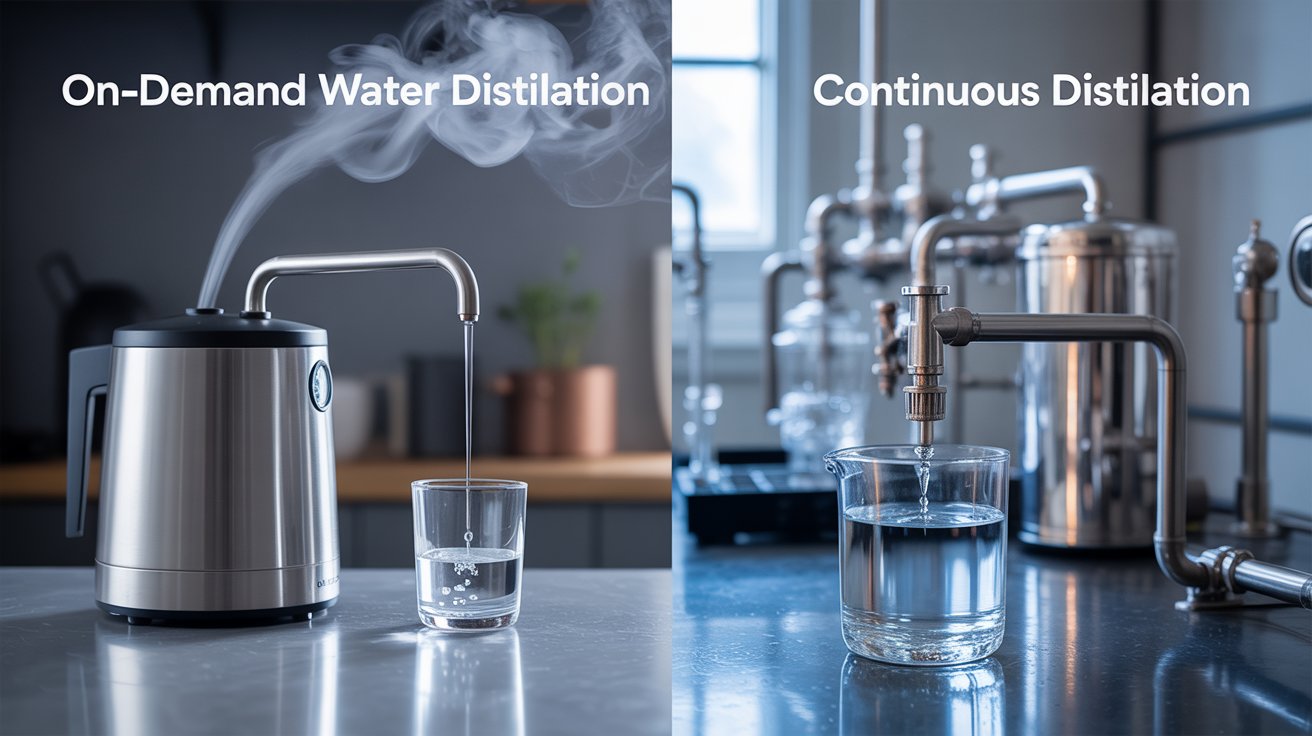

On-Demand Water Distillation vs. Continuous Distillation

On-demand and continuous water distillation represent two different philosophies in water purification, each with its unique operational characteristics. Understanding these differences is crucial for selecting the most appropriate system for specific needs.

Fundamental Operational Differences

The primary distinction between on-demand and continuous distillation lies in their processing methods. On-demand distillation involves batch processing, where water is distilled in batches as needed. In contrast, continuous distillation operates non-stop, providing a constant flow of distilled water.

- On-demand systems are ideal for intermittent use or smaller quantities.

- Continuous systems are better suited for high-demand applications or where a constant supply is necessary.

Design and Setup Variations

The design and setup of on-demand and continuous distillation systems also vary significantly. On-demand systems are typically more compact and can be designed for specific batch sizes. Continuous distillation systems, however, require more complex setups, including larger tanks and more sophisticated control mechanisms.

When choosing between these systems, it’s essential to consider factors such as space, energy consumption, and maintenance requirements. By understanding the fundamental differences in operation and design, users can make informed decisions about their water distillation needs.

How On-Demand Distillation Systems Work

For those looking for a compact solution, on-demand distillation systems offer a practical approach to water purification. These systems are designed to produce purified water on demand, making them ideal for smaller-scale applications such as households or small businesses.

Technical Components and Process Flow

On-demand distillation systems typically consist of a heating element, a distillation chamber, and a condenser. The process begins with the heating element warming the water to its boiling point, turning it into steam. This steam then rises into the distillation chamber, where it is separated from contaminants. Finally, the steam is cooled in the condenser, converting it back into liquid form, resulting in purified water.

Common On-Demand Distiller Models and Capacities

Various models of on-demand distillers are available, catering to different needs and capacities. Some popular models can produce up to 4 liters of purified water per hour, making them suitable for daily household needs. When choosing an on-demand distiller, it’s essential to consider factors such as energy efficiency, maintenance requirements, and production capacity to ensure it meets your specific requirements.

In summary, on-demand distillation systems provide a convenient and efficient method for water purification. By understanding their technical components and process flow, users can make informed decisions about their water purification needs.

The Continuous Distillation Process Explained

The continuous distillation process is designed to handle high-volume water purification needs. This method is particularly useful for large-scale industrial applications where a constant supply of purified water is crucial. Continuous distillation systems are engineered to operate around the clock, providing a steady flow of distilled water.

System Components and Functionality

Continuous distillation systems consist of several key components, including a distillation chamber, heating element, condenser, and control system. The distillation chamber is where the water is heated to produce steam, which is then condensed back into liquid form. The control system monitors the process, ensuring that the water meets the required purity standards.

Key components include:

- Distillation chamber

- Heating element

- Condenser

- Control system

Popular Continuous Distillation Systems in the Market

Several manufacturers offer continuous distillation systems, each with its unique features and benefits. For instance, some systems are designed for energy efficiency, while others focus on maximizing purity levels. When selecting a continuous distillation system, it’s essential to consider factors such as production capacity, maintenance requirements, and energy consumption.

| System Model | Production Capacity | Energy Consumption |

|---|---|---|

| Model A | 1000 L/h | 3 kW |

| Model B | 2000 L/h | 5 kW |

| Model C | 500 L/h | 2 kW |

As noted by industry experts, “Continuous distillation offers a reliable and efficient method for large-scale water purification, making it an ideal choice for industrial applications.” This highlights the importance of continuous distillation in meeting the high demands of purified water in various industries.

Water Quality Comparison Between Methods

When it comes to water purification, the debate between on-demand and continuous distillation methods often centers on the quality of the water produced.

Both methods have their strengths in producing high-quality distilled water, but they differ in their approach and outcomes.

Purity Levels and Contaminant Removal Efficiency

On-demand distillation systems heat water to its boiling point, effectively removing contaminants and producing very pure water.

Continuous distillation systems, on the other hand, maintain a constant flow of water through the distillation process, also achieving high purity levels.

A comparison of the two methods reveals that both are effective, but continuous distillation may have a slight edge in maintaining consistent purity due to its continuous operation.

| Distillation Method | Purity Level | Contaminant Removal Efficiency |

|---|---|---|

| On-Demand | Very High | Effective |

| Continuous | Very High | Highly Effective |

Taste and Mineral Content Differences

The taste and mineral content of water produced by on-demand and continuous distillation can vary.

On-demand systems can sometimes result in water that tastes flat due to the removal of minerals.

Continuous distillation systems may retain slightly more minerals, depending on the specific system design, potentially affecting the taste.

In conclusion, while both on-demand and continuous distillation methods produce high-quality water, the differences lie in their operational efficiencies and the nuances of the water quality they produce.

Energy Efficiency and Resource Utilization

Distillation techniques vary significantly in their energy efficiency, impacting their environmental footprint and operational costs. Understanding the energy efficiency of different distillation methods is crucial for households and businesses aiming to minimize their energy consumption.

Power Consumption Analysis

A key aspect of energy efficiency in water distillation is power consumption. Continuous distillation systems generally consume less energy compared to on-demand distillation systems because they operate at a consistent rate, allowing for better energy management.

For instance, a continuous distillation system might consume approximately 3-5 kWh of electricity per gallon of water distilled, whereas on-demand systems can surge up to 6-8 kWh per gallon during operation. This difference is significant, especially for high-volume users.

| Distillation Method | Average Energy Consumption (kWh/gallon) |

|---|---|

| Continuous Distillation | 3-5 |

| On-Demand Distillation | 6-8 |

Energy-Saving Features in Modern Distillers

Modern distillers have incorporated various energy-saving features to enhance their efficiency. These include advanced insulation materials, optimized heating elements, and smart sensors that monitor and adjust energy consumption in real-time.

For example, some modern continuous distillation systems come equipped with heat recovery technology, which reutilizes the heat generated during the distillation process, thereby reducing overall energy consumption.

By adopting these energy-efficient technologies, households and businesses can significantly reduce their operational costs while contributing to a more sustainable environment.

Water Output and Production Rates

Water output is a critical consideration for those choosing between on-demand and continuous water distillation systems. The production rate of a water distillation system can significantly impact its suitability for various applications.

On-Demand Production Capabilities

On-demand water distillation systems produce water in batches, making them suitable for applications where water demand is intermittent or variable. These systems can be designed to produce a specific volume of water per cycle, ranging from a few liters to several gallons. The batch production capability allows for flexibility in managing water supply according to immediate needs.

- Typical production capacities range from 4 to 12 liters per cycle.

- Systems can be configured to run multiple cycles in a short period to meet higher demands.

- On-demand systems are ideal for households or small businesses with fluctuating water needs.

Continuous Flow Output Metrics

Continuous distillation systems, on the other hand, provide a constant flow of distilled water, making them ideal for applications requiring a steady supply. The output of these systems is measured in liters per hour (L/h) or gallons per minute (GPM). Continuous flow ensures that there’s always a supply of fresh, distilled water available.

- Output rates can vary significantly, from a few L/h to over 100 L/h.

- These systems are often used in laboratories, hospitals, and large commercial establishments.

- The ability to provide a consistent flow makes them suitable for processes that require a continuous water supply.

Maintenance Requirements and System Longevity

Maintenance plays a pivotal role in the operational lifespan and effectiveness of both on-demand and continuous distillation systems. Proper upkeep not only ensures the quality of the distilled water but also impacts the longevity of the equipment.

Cleaning and Upkeep for On-Demand Systems

On-demand distillation systems require regular cleaning to prevent scale buildup and maintain efficiency. Descaling is a critical process that should be performed every few months, depending on usage and water hardness. Additionally, the heating elements and other parts should be inspected regularly for signs of wear.

“Regular maintenance is key to extending the life of your on-demand water distiller,” says a leading manufacturer. “Neglecting maintenance can lead to reduced performance and potentially shorten the system’s lifespan.”

Maintaining Continuous Distillation Equipment

Continuous distillation systems, while often more complex, also require consistent maintenance. This includes regular checks on the distillation column, condenser, and other critical components. Automated cleaning systems can be beneficial in reducing manual maintenance tasks.

A comparison of water distillation methods reveals that continuous systems may require more frequent maintenance due to their constant operation. However, modern designs have incorporated features to minimize downtime and simplify upkeep.

By understanding the maintenance needs of both on-demand and continuous distillation systems, users can make informed decisions about which distillation technique best suits their needs and ensures long-term satisfaction.

Cost Analysis: Initial Investment vs. Long-Term Value

Investing in a water distillation system requires a thorough analysis of both initial and ongoing costs. When comparing on-demand and continuous distillation methods, it’s essential to consider various financial factors to determine the most cost-effective solution for your needs.

Purchase and Installation Expenses

The initial investment for water distillation systems varies significantly between on-demand and continuous models. On-demand systems typically have a lower upfront cost, ranging from $500 to $2,000, depending on the brand and capacity. In contrast, continuous distillation systems can be more expensive, with prices starting at around $2,000 and going up to $10,000 or more for larger commercial units.

| System Type | Initial Cost | Installation Cost |

|---|---|---|

| On-Demand | $500-$2,000 | $100-$500 |

| Continuous | $2,000-$10,000 | $500-$2,000 |

Operational Costs Over Time

Operational costs, including energy consumption and maintenance, also differ between the two systems. On-demand distillation systems tend to have higher operational costs due to the energy required for each distillation cycle. Continuous systems, while more energy-intensive initially, can be more cost-effective in the long run, especially for high-volume users.

Return on Investment Considerations

When evaluating the return on investment (ROI), it’s crucial to consider both the initial costs and the long-term savings. Continuous distillation systems, despite their higher upfront costs, can offer significant savings over time, particularly for businesses or households with high water purification demands.

In conclusion, while on-demand water distillation systems may offer lower initial costs, continuous distillation systems can provide better long-term value for those with substantial water purification needs. Carefully assessing your specific requirements and considering both the initial investment and ongoing expenses will help you make an informed decision.

Ideal Applications and Use Cases

The suitability of on-demand versus continuous water distillation largely depends on the specific use case and requirements. Different scenarios call for different approaches to water purification, and understanding these needs is crucial for making an informed decision.

Best Scenarios for On-Demand Distillation

On-demand water distillation is ideal for applications where water demand is intermittent or variable. This method is particularly useful in laboratory settings, where precise control over water purity is necessary, and in small-scale industrial processes. On-demand distillation systems are also beneficial for residential use, providing a reliable source of clean drinking water without the need for large storage tanks.

When Continuous Distillation Makes More Sense

Continuous distillation is more suitable for applications requiring a constant and high-volume supply of purified water. This method is commonly used in large industrial processes, pharmaceutical manufacturing, and power generation facilities. Continuous distillation systems can provide a steady flow of purified water, making them ideal for operations where water is a critical component.

| Application | On-Demand Distillation | Continuous Distillation |

|---|---|---|

| Laboratory Settings | Yes | No |

| Residential Use | Yes | No |

| Large Industrial Processes | No | Yes |

| Pharmaceutical Manufacturing | No | Yes |

In conclusion, the choice between on-demand and continuous water distillation should be based on the specific requirements of the application. By understanding the ideal use cases for each method, users can select the most appropriate water purification method for their needs.

Conclusion: Choosing the Right Distillation Method for Your Needs

After exploring the differences between on-demand and continuous water distillation, it’s clear that each method has its unique benefits and applications. The comparison of water distillation methods reveals that on-demand systems are ideal for smaller-scale, intermittent use, while continuous distillation is better suited for high-volume, consistent production.

When deciding between these two methods, consider your specific needs, such as water quality requirements, energy efficiency, and maintenance capabilities. The benefits of continuous distillation include higher production rates and potentially lower operational costs, making it a viable option for commercial or industrial applications.

Ultimately, understanding the strengths and limitations of each distillation method will help you make an informed decision. By choosing the right distillation system, you can ensure access to clean, purified water that meets your needs, whether for personal, commercial, or industrial use.