Have you ever wondered how your water distiller transforms steam back into pure, clean water? The magic happens in the condenser coils – the unsung heroes of the distillation process. Think of these coils like the cold bathroom mirror that collects droplets when you take a hot shower. In your distiller, they perform a similar but more precise function, ensuring that only pure water makes it into your glass.

Understanding how condenser coils in water distiller systems work isn’t just interesting science – it’s practical knowledge that can help you maintain your distiller and ensure you’re always getting the purest water possible. Let’s explore the fascinating journey of how steam transforms back into liquid gold in these essential components.

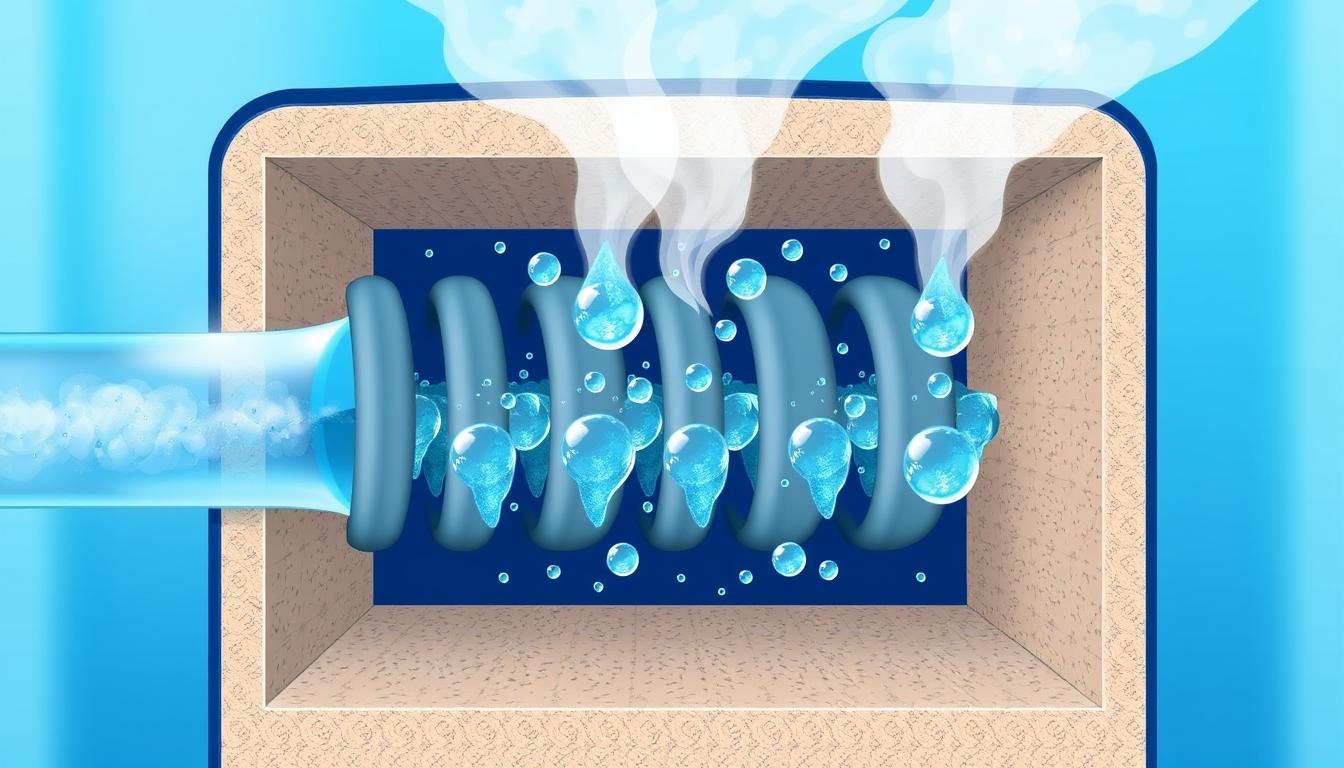

The Cooling Process: Steam’s Journey Through the Coils

When water boils in the heating chamber of your distiller, it transforms into steam, leaving behind contaminants, minerals, and impurities. This purified steam then travels upward and enters the condenser coils, beginning a remarkable transformation process.

The condenser coils work through a simple but effective principle: temperature difference. As the hot steam (typically around 212°F or 100°C) enters the coils, it encounters the much cooler metal walls. This is similar to how a cold soda can “sweats” on a hot summer day – the temperature difference causes condensation.

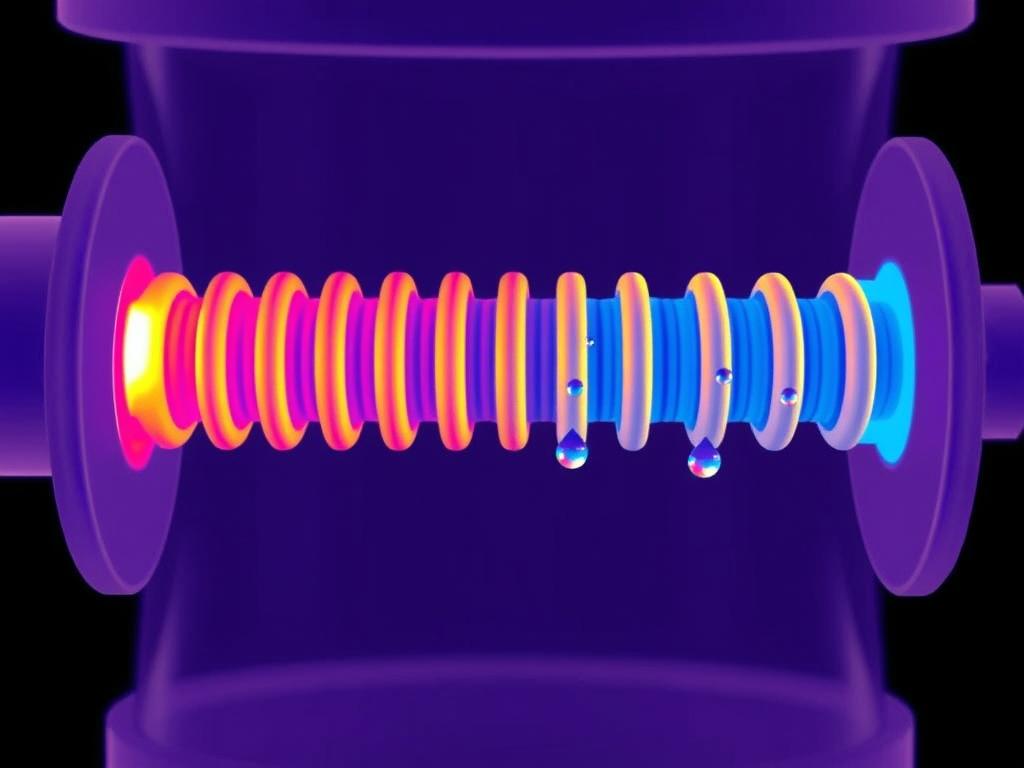

Temperature gradient visualization showing heat transfer in condenser coils

As the steam touches these cooler surfaces, it rapidly loses heat through conduction. The coil material absorbs this heat and transfers it to the surrounding air or water cooling system. This heat loss causes the steam molecules to slow down and draw closer together, transforming from gas back to liquid – a process called condensation.

The newly formed water droplets then trickle down the inside walls of the coil, following gravity’s pull. Many distillers use a spiral or zigzag coil design to maximize the cooling surface area and ensure complete condensation before the water reaches your collection container.

Water droplets forming and flowing inside condenser coils

Material Matters: Aluminum vs. Stainless Steel Coils

The material of your condenser coils plays a crucial role in both efficiency and water purity. The two most common materials are aluminum and stainless steel, each with distinct advantages and considerations.

Aluminum Coils

- More affordable option for budget-conscious buyers

- Excellent thermal conductivity for efficient cooling

- Lightweight and easy to handle during maintenance

- Works well with relatively clean water sources

Aluminum Coils

- More susceptible to corrosion over time

- May leach small amounts of aluminum into water

- Shorter lifespan, especially with hard water

- Requires more frequent cleaning and maintenance

Stainless Steel Coils

- Superior corrosion resistance for longer lifespan

- No metal leaching concerns for purest water quality

- Extremely durable even with hard water sources

- Easier to clean and maintain over time

Stainless Steel Coils

- Higher initial investment cost

- Slightly less thermal conductivity than aluminum

- Heavier weight can make handling more difficult

- May require more energy for the same cooling effect

For most homeowners, stainless steel condenser coils in water distiller systems represent the better long-term investment. While they cost more initially, their durability and resistance to corrosion mean fewer replacements and maintenance issues over time. They’re particularly valuable if you have hard water, which can accelerate wear on aluminum coils.

Design Efficiency: How Coil Shape Affects Performance

The design of condenser coils significantly impacts how efficiently your water distiller operates. Various aspects of coil design – from shape and length to surface area and placement – all work together to determine distillation speed, energy use, and water purity.

Coil Shape and Surface Area

The most efficient condenser coils maximize contact between steam and the cooling surface. Zigzag or spiral designs work like a maze, forcing steam to travel a longer path and spend more time cooling. This extended contact ensures more complete condensation and purer water.

Spiral Coils

Spiral designs create a compact, efficient cooling system that fits in smaller distillers. The circular pattern allows for natural water flow while maximizing cooling surface in minimal space. These are common in countertop distillers where space efficiency matters.

Serpentine/Zigzag Coils

These coils use a back-and-forth pattern that extends the steam’s journey. The multiple direction changes force steam to slow down, ensuring more thorough cooling. This design is excellent for ensuring complete condensation in larger distillation systems.

Cooling Method Integration

Condenser coils work in conjunction with a cooling system – typically air or water cooling. In air-cooled systems, a fan blows room-temperature air across the coils. Water-cooled systems circulate cool water around the outside of the coils, providing more efficient heat transfer.

Water-cooled systems typically achieve faster and more efficient condensation but require a continuous water supply. Air-cooled systems are simpler and don’t waste water but may operate more slowly, especially in warm environments.

Maintenance Signs: When Your Condenser Coils Need Attention

Like any component in your water distiller, condenser coils require regular maintenance and occasional replacement. Recognizing the warning signs early can prevent more serious issues and ensure your distiller continues producing pure water efficiently.

Warning Signs to Watch For

Reduced Water Output

If your distiller is producing less water than usual, mineral buildup inside the condenser coils may be restricting flow. This is often the first sign that cleaning is needed. Compare your current output to what you typically expect from a distillation cycle.

Strange Tastes or Odors

Pure distilled water should be tasteless and odorless. If you notice any unusual flavors or smells, your condenser coils might be contaminated or corroding. This is particularly common with older aluminum coils that have begun to degrade.

Visible Corrosion or Discoloration

Inspect your condenser coils regularly for signs of corrosion, particularly at connection points. Bluish-green deposits on copper coils or white/gray scaling on aluminum indicate chemical reactions that could affect water quality.

Unusual Noises During Operation

Popping, hissing, or gurgling sounds during the condensation process may indicate steam is not flowing properly through the coils. This could be due to partial blockages or improper cooling that prevents smooth condensation.

Before and after cleaning heavily scaled condenser coils

Troubleshooting and Maintenance Tips

Regular Cleaning

For minor buildup, a solution of food-grade citric acid and water (1:10 ratio) can be circulated through your coils. Plug one end, fill with the solution, and let it sit for 30-60 minutes before rinsing thoroughly. For stubborn deposits, white vinegar is an effective alternative.

Professional Assessment

If cleaning doesn’t restore performance, or if you notice any leaks or significant corrosion, it’s time to consult a professional. Continuing to use damaged coils can affect water quality and potentially damage other components of your distiller.

Why Condenser Coils Matter for Pure Water

The condenser coils in your water distiller are more than just metal tubes – they’re the crucial final step in transforming contaminated water into pure, safe drinking water. By understanding how these components work, the importance of proper materials, and the signs of wear, you can ensure your distiller continues to provide the highest quality water for years to come.

Regular maintenance of your condenser coils not only extends the life of your distiller but also protects your investment in pure water. Whether you choose aluminum for budget-friendliness or stainless steel for longevity, keeping those coils in top condition is essential for efficient operation and the purest possible water.

Need to Replace Your Condenser Coils?

If you’ve noticed reduced performance or visible damage to your distiller’s condenser coils, it may be time for a replacement. High-quality stainless steel coils provide the best long-term value and ensure the purest water possible.

Premium stainless steel replacement condenser coils for various distiller models